The press conference kicked off with the wonderful performances of teachers from the art team of “Huayin Laoqiang”, an intangible cultural heritage of China. The roar of Huayin Laoqiang expressed the enthusiasm and pride of the people in Sanqin, and at the same time let the participants feel the warm hospitality of BHS

Mr. Wu Xiaohui, CEO of BHS China, delivered a speech on stage. He introduced the current organizational structure of BHS China and the vision of “2025 Future cigarette box Cardboard Factory” and “2025 Future Carton Factory”. Mr. Wu also said that in the post-epidemic era, the national economy is recovering and the demand is strong. BHS will continue to support the cigarette box packaging business of colleagues in the industry more vigorously.regular cigarette box

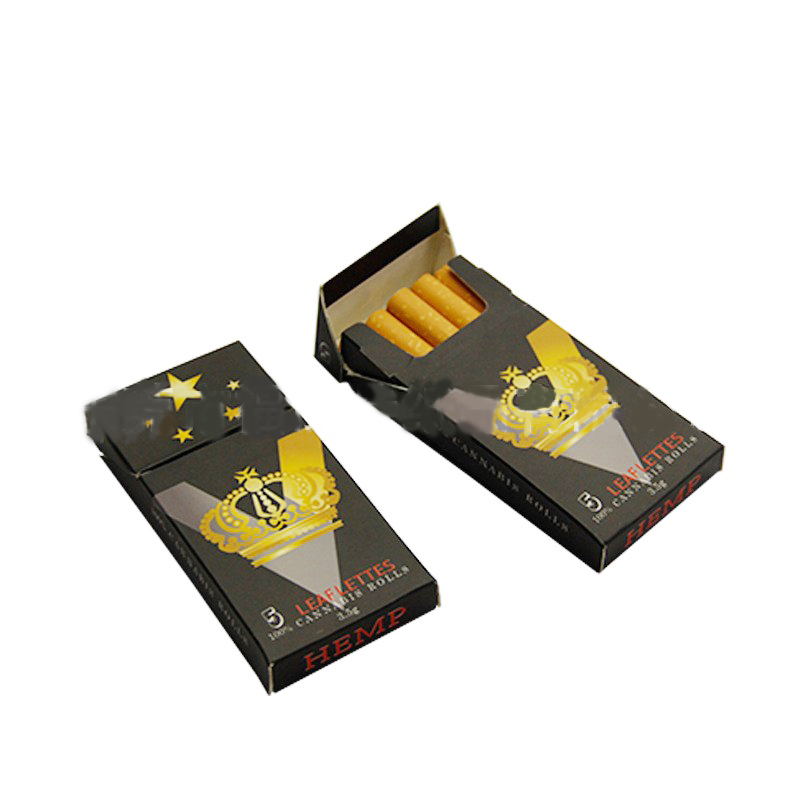

At present, the entire cigarette box corrugated industry is entering a new era of high-speed, efficient and intelligent production. In order to achieve the goal and empower the industry, BHS, BDS, and BTS have released several new cigarette box products

Mr. Chen Zhigang, Sales Director of BHS, introduced to everyone that BHS had organized the Belt and Road Initiative in the Midwest as early as 2018, visited many cigarette box carton factory customers along the route, investigated the market conditions in the Midwest through on-the-spot visits, and deeply analyzed customer order structures and production needs. Over the years, BHS has been exploring what kind of tiles are needed in the Midwest market. Although this process has been disrupted by the epidemic, BHS has never stopped.

Today BHS has brought a new Star of Excellence series cigarette box corrugated cardboard production line – “Excellent Sail”, the design speed of this corrugated line is 270m/min, the door width is 2.5 meters, and it can achieve a monthly output of 13.8 million square meters of corrugated cigarette box cardboard .preroll king siae box

Mr. Chen also disclosed at the press conference that the price of the whole line is 21.68 million yuan, and considering the current order situation and the production capacity of the BHS Shanghai factory, a maximum of 4 “excellent sailing” can be delivered in 2023, and the contract will be signed before 5.31. The BHS production management system will be presented as a gift.

BHS hopes that customers can easily own the entire BHS line even when the initial investment budget is limited, so that the investment cost can be recovered in the shortest possible time, and the tile line can be upgraded in the near future, which is in line with the more efficient and smarter future paperboard factory. need. At the same time, it provides the hardware and software basis for the realization of online digital printing machines in the future.

Mr. Ge Yan, Sales Manager of BHS Digital Printing Machines, announced to everyone that a new cigarette box product of BHS that has attracted the most attention from the market in the past two years – DPU digital printing machines.vape packaging

Mr. Ge introduced that digital cigarette boxprinting had been established in BHS Germany as early as 2010. After more than ten years of research and development, the first 2.8-meter DPU digital printing machine will be delivered in Germany in 2020, and 35 million square meters of corrugated digital packaging will be produced. product. In 2022, the Asia-Pacific version of BHS digital printing machines also started formal testing. This equipment inherits BHS Germany’s more than ten years of experience in digital printing, and combines BHS’s leading position in traditional cigarette box cardboard production lines. The transformation of smart products.

The maximum width of this DPU digital cigarette box printing machine is 1800mm-2200mm, the maximum speed is 150m/min-180m/min, the maximum production capacity per hour is 16000m2-22000m2, CMYK additional 3 colors are reserved, and the pre-coating and varnishing function is optional to achieve printing effect It is 1200DPI. At the same time, the order change speed of this digital cigarette box printing machine is only one minute, the delivery time of the entire product is reduced to one day, the process loss is reduced to 1%, and the operator only needs 1-2 people.

Post time: May-04-2023