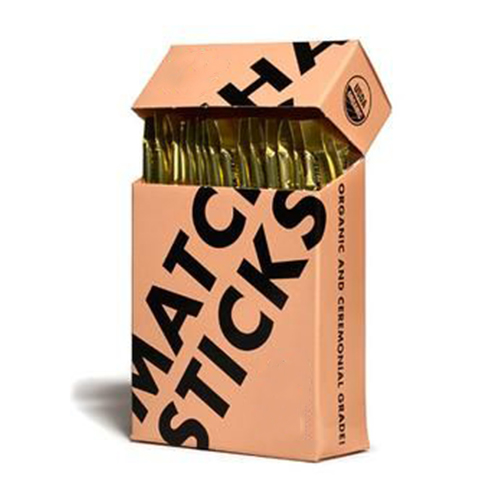

Shenzhen Packaging Exhibition understands that packaging refers to the process of placing goods or items into appropriate containers, packaging bags, cartons, bottles, etc., aiming to achieve multiple purposes cannabis cigarette box such as protection, transportation, display, and sales. The core function of packaging is to ensure the integrity and safety of products and avoid damage or deterioration during transportation and storage. At the same time, packaging is also an important way to convey product information and brand concepts to consumers, helping to enhance the market appeal and competitiveness of products.

The design and material selection of cannabis cigarette box packaging are flexible and diverse to meet different product characteristics and market needs. Depending on the materials used, packaging can be divided into cardboard packaging, plastic packaging, metal packaging, glass packaging, fiber packaging, etc. Each material has its own unique advantages and applicability, such as cardboard packaging is environmentally friendly and low-cost, plastic packaging is waterproof and durable, metal packaging is pressure-resistant and beautiful, glass packaging is transparent and high-end, etc.

Packaging can also be classified according to use, including consumer packaging, industrial packaging and transportation packaging. Consumer product packaging focuses on beauty and attractiveness to attract consumers to buy; industrial packaging emphasizes protection and functionality to ensure the safety of products during the industrial production process; while transportation packaging focuses on durability and convenience to facilitate the long-distance transportation of products. Safe arrival at destination during transportation.

Shenzhen Packaging Exhibition understands that cannabis cigarette box packaging is not only a tool for product protection and transportation, but also an important means of brand building and marketing. Through careful design and clever use, packaging can increase the added value of products, enhance consumers’ desire to purchase, and inject strong impetus into the sustainable development of enterprises. The packaging industry is a broad and diversified field, covering many aspects from raw material production, cannabis cigarette box packaging design, manufacturing and processing to sales and logistics. With the development of the global economy and changing consumer demands, the packaging industry is experiencing rapid innovation and change.

The upstream of the packaging industry chain mainly involves the supply of raw materials, including paper, plastic particles, metal sheets, glass and various fiber materials. These raw materials play a fundamental role in the packaging industry.

Shenzhen Packaging Exhibition learned that the downstream applications of the packaging industry are extremely wide, covering multiple industries such as food and beverages, household appliances, consumer electronics, e-commerce logistics, machinery and equipment, chemical products, daily chemicals, and pharmaceutical and health products. In these industries, packaging is not only an important means to protect products and improve product sales, but also directly affects the brand image and market competitiveness of the product.

Especially in the papermaking industry, its downstream industries are very diverse, covering almost all fields such as food and beverages, household appliances, consumer electronics, e-commerce logistics, machinery and equipment, chemicals, daily chemicals, medicine and health care. This shows that packaging plays a vital role in business and daily life.

Development status of cannabis cigarette box packaging industry

China’s packaging industry has strong social demand and its scientific and technological content is increasing year by year. It has become an indispensable and important part of the national economy. With the transfer of global processing and manufacturing industries and strong support from the state, the number of enterprises in my country’s packaging industry is steadily increasing. According to the latest statistics, the number of packaging companies above designated size in my country will reach 9,860 in 2022, an increase of 1,029 compared to 2021.

In terms of operating income, my country’s packaging enterprises above designated size achieved revenue of 1,229.334 billion yuan in 2022, an increase of 25.153 billion yuan compared with 2021. In terms of industry segments, paper packaging and plastic film packaging occupy the largest market share, accounting for a total of 31.09%. Followed by the paper and cardboard container industry, accounting for 24.77%. In addition, plastic packaging boxes and containers, metal packaging containers and materials, special equipment for plastic processing, glass packaging containers, cork products and other wood products also occupy a certain market share.

In terms of profits, in 2022, my country’s packaging enterprises above designated size achieved a total profit of 63.107 billion yuan. Among them, the plastic film industry has a high profit share, reaching 33.91%. Paper and cardboard containers, plastic packaging boxes and containers, special equipment for plastic processing, metal packaging containers and materials, and glass packaging containers also account for a certain proportion of profits.

In terms of foreign trade, my country’s packaging industry has maintained a surplus. From January to December 2022, the national packaging industry’s cumulative export volume was US$55.252 billion, a year-on-year increase of 12.85%; its cumulative import volume was US$14.111 billion, a year-on-year decrease of 15.05%. In terms of exports, plastic packaging is my country’s main export product type, accounting for 65.91%. In terms of imports, plastic packaging also occupies a dominant position, accounting for 90.13% of the import value.

From the perspective of geographical distribution at the Shenzhen cannabis cigarette box Packaging Exhibition, the main export provinces of my country’s packaging industry in 2022 are Guangdong Province, Zhejiang Province and Jiangsu Province, accounting for 26.40%, 21.01% and 11.90% of the export value respectively. In terms of imports, Jiangsu, Guangdong, and Shanghai are the main importing provinces in my country’s packaging industry, accounting for 29.04%, 24.10%, and 18.76% of the import value respectively. The packaging industry in these areas has developed rapidly and foreign trade is active, making important contributions to the overall development of my country’s packaging industry.

Competitive landscape of packaging industry

Driven by the rapid growth of my country’s national economy, the packaging industry has also achieved significant leap-forward development. The huge market potential and superior development environment have attracted the influx of many well-known domestic and foreign enterprises and private capital. Large-scale packaging companies are more competitive due to their economies of scale in raw material procurement, production and logistics, and gradually occupy market share. At the same time, as environmental protection requirements become increasingly stringent, technology and materials in the packaging industry are also constantly improving, causing some small companies to gradually withdraw from the market. Especially for listed companies, it is easier for them to obtain low-cost financial support for rapid business expansion.

Shenzhen Packaging Exhibition learned that in recent years, kraft paper has become the paper of choice in many fields due to its high strength, versatility and low impact on the environment. In fact, one of its main features is that it is 100% recyclable and environmentally friendly.

What is kraft paper

The Shenzhen Packaging Exhibition learned that kraft paper is paper or cardboard produced from chemical pulp produced by the kraft paper process. Due to the kraft pulp process, the original kraft paper is tough, water-resistant, tear-resistant, and has a yellow-brown color.

Kraft pulp is darker than other wood pulps, but can be bleached to produce a very white pulp. Fully bleached kraft pulp is used in the manufacture of high quality paper where strength, whiteness and resistance to yellowing are important.

The difference between kraft paper and ordinary paper:

Some people may say, it’s just paper, what’s so special about it? Simply put, kraft paper is stronger.

Due to the kraft paper process mentioned earlier, more wood is stripped away from the kraft paper pulp, leaving more fibers behind, giving the paper its tear-resistant and durable properties.

Original color kraft paper is often more porous than ordinary paper, which makes its printing effect slightly worse, but it is very suitable for some special processes, such as embossing or hot stamping.

The history and production process of kraft paper

Shenzhen Packaging Exhibition learned that kraft paper is a commonly used packaging material and is named after the kraft paper pulping process. The kraft paper process was invented by Carl F. Dahl in Danzig, Prussia, Germany in 1879. Its name comes from German: “Kraft” means strength or vitality.

The basic ingredients for making kraft pulp are wood fiber, water, chemicals and heat. Kraft pulp is made by mixing wood fibers with a solution of caustic soda and sodium sulfide and cooking it in a digester.

The pulp goes through manufacturing processes and process controls such as dipping, cooking, pulp bleaching, beating, sizing, whitening, purification, screening, shaping, dehydration and pressing, drying, calendering, and coiling, and finally produces kraft paper.

Application of kraft paper in cannabis cigarette box packaging

Today, kraft paper is mainly used for corrugated boxes, as well as plastic hazard-free paper used in paper bags such as cement, food, chemicals, consumer goods, flour bags, etc.

Due to the durability and practicality of kraft paper, corrugated cartons are very popular in the express logistics industry. Cartons can protect products well and can withstand harsh transportation conditions. In addition, the price and cost are in line with corporate development.

Shenzhen Packaging Exhibition learned that kraft paper boxes are also often used by companies to achieve sustainable development goals, and clearly depict environmental protection initiatives through the plain and original appearance of brown kraft paper. Kraft paper is extremely versatile and offers a variety of innovative packaging in today’s packaging industry.

Generally we will choose bubble film to package the product

The advantage of bubble wrap is shock absorption and buffering of items. Especially during the handling and transportation of items, using bubble wrap to pack items can protect items well and avoid collision and damage. At present, some handicraft industries, automobile or motorcycle industries will choose bubble film to package and transport goods, which is not only affordable and convenient, but also can effectively protect the goods.

The bubble film is made of resin material. The middle layer of the bubble film is filled with air, so we will find that the bubble film is very light and has good elasticity. Therefore, the bubble film has good air permeability. In addition, bubble film also has outstanding features of anti-corrosion and moisture resistance. It is precisely because of its unique structure and materials that the bubble film will not absorb moisture and has certain moisture-proof properties. In addition, the bubble film can also effectively prevent corrosion in some acid and alkali corrosive media, such as some electronic products, audio-visual products or some Cosmetics can be packaged with bubble wrap to effectively protect them.

Shenzhen cannabis cigarette box Packaging Exhibition learned that, finally, bubble film also has good sound insulation properties, so during the transportation of some large items, the use of bubble film can play a sound insulation role, especially for some items transported in summer, the use of bubble film packaging is appropriate.

Bubble wrap is colorless, odorless and non-toxic. Not only does it have good performance and advantages, but it can also be customized in different sizes and shapes according to our needs to meet more application scenarios and usage needs.

The difference between gourd film and bubble film

Shenzhen Packaging Exhibition learned that the first point is the size of the bubble after inflation. After the cannabis cigarette box bubble film is inflated, the bubbles formed are relatively small and each bubble is independent of each other. Positions here are not protected if the bubble bursts. Calabash membrane is different. The bubbles formed after the gourd film is inflated are larger, and more gas can withstand greater impact and protect the product. At the same time, the bubbles of the gourd film are connected in series. If a bubble is squeezed and deformed by a large impact force, the gas in the bubble will be squeezed onto other bubbles to avoid damage due to high pressure. When this force disappears, the gas returns to its original bubble state and returns to its original shape. Like bubble film, gourd film can wrap products in a wrapping manner and protect products in all directions without blind spots.

The second point is cost. From the purchase price point of view, bubble film and gourd film are almost the same. But in terms of overall cost, gourd film is more suitable. Why do you say this? Because the bubble film is inflated after it is produced. It is very large and takes up a lot of space and resources. Calabash membrane is different. After the gourd film is produced, it is stored in roll film. A single sheet is only as thick as two A4 papers, saving a lot of storage and transportation space and costs.

Post time: Apr-27-2024