The product packaging process will be affected by the weather and environmental factors. Because the circulation range of UK cigarette packaging products varies greatly regardless of the regional meteorological and environmental conditions. Packaging engineering designers need to understand the changing rules of meteorological environmental conditions, study the impact of meteorological environmental conditions on the performance and quality of packages, and provide necessary protection so that the packaging can meet product packaging requirements within a certain storage period or shelf life, and reduce the circulation process losses in.

Meteorological factors affecting UK cigarette packaging technology refer to weather conditions, which mainly include temperature, humidity, rain and snow, wind and solar radiation, etc.

1. Diarrhea

A physical quantity that expresses the degree of hotness and coldness of the atmosphere, namely air temperature. The temperature in the atmosphere generally refers to the temperature observed by the weather station, that is, the air temperature at a height of 2 meters from the ground, without direct sunlight and with good air circulation.

Latitude is the main factor in temperature changes in various places, followed by local terrain and altitude. Our country has a vast territory, with significant differences in altitude and climate in various regions. For example, the highest temperature in the Turpan Basin once reached 48°C, while Mohe, Heilongjiang, experienced temperatures as low as minus 50°C. The eastern region has tropical, subtropical, warm temperate, frigid and other climate zones from south to north. On the Qinghai-Tibet Plateau, there are high mountain village zones and year-round frozen climate zones. The surface temperature has diurnal and annual changes, which makes the air temperature have diurnal and annual changes. This change is cyclical and is caused by changes in the ground radiation budget.

Daily temperatures have a maximum and minimum value. The lowest temperature occurs near sunrise. After sunrise, the air gradually rises, reaching the highest value between 14 and 15 noon, and then gradually drops until sunrise. The difference between the highest temperature and the lowest temperature in a day and night is called the diurnal temperature range, which is related to latitude, season, topography, surface properties, weather conditions and altitude.

The annual change in temperature also has a maximum value and a minimum value (except for areas near the equator). The highest temperature of the year occurs in summer, mostly in July on the mainland and in August on the ocean. The lowest temperature occurs in winter, mostly in January on the mainland and in February on the ocean. The difference between the average temperature of the hottest month and the average temperature of the coldest month in a year is called the annual temperature range. Likewise, its size is also related to factors such as latitude, topography, ground properties, weather conditions and altitude. For example, in the tropics, the average annual temperature range on the continent can reach 20°C, while in coastal areas it is about 5°C, and the annual temperature range is not large. The annual range is very large in the temperate zone, and increases with increasing latitude and depth inland. The annual range along the ocean coast is about 15°C, while on the continent it can reach 50~60°C.

Daily changes in temperature will have an impact on the quality of packaging. In the dry tropical areas with the largest diurnal variation, the diurnal temperature range can be close to 30°C within 8 hours from before to after sunrise. Large daily temperature differences may cause severe relative humidity changes in closed packages.

The main functions of food packaging are to prevent food from spoiling in the circulation environment, ensure quality, prevent food from being contaminated by microorganisms and dirt, use mechanized and automated packaging to improve production efficiency, make production more rational, and promote and improve food circulation. and business management to increase the commodity value of food. To this end, food packaging adopts a series of new technologies and processes, including retort bag packaging food technology, quick-frozen food technology, fresh-keeping UK cigarette packaging technology, aseptic packaging technology, etc. Taking the aseptic packaging of fruit juice drinks as an example, we will analyze the formulation process of beverage product packaging process regulations 1. Characteristics of fruit drinks and specific requirements for packaging

Juice is made from different fruits, which vary in composition and properties. The main factors related to packaging are the acidity, enzymes, vitamin C, color and aroma of the juice.

All fruits and juices contain organic acids to varying degrees. Organic acids can maintain the unique aroma of fruits, give people taste enjoyment, and are beneficial to human health. Therefore, packaging standards must not only protect the organic acids in fruit juices, but also prevent organic acids from forming. The corrosive effect of acids on packaging. The pH of fruit juice food uk cigarette packaging is generally below 4.5. Bacteria will not grow under normal conditions. The deterioration of fruit juice is mainly caused by yeast and mold. At room temperature, raw juices deteriorate due to alcoholic fermentation, which in turn causes acidification of the alcohol and fruit due to yeast or mold growth on the surface. To prevent spoilage, it should be instantaneously sterilized by high temperature

That is, use a plate or tube heat exchanger to heat the juice to 110°C and keep it for 15 seconds, or filter and add preservatives to eliminate the juice or inhibit the damaging effects of yeast. Vitamin C in juice is easily lost, especially in metal containers with poor iron, copper or tin plating. Due to the presence of metal ions, vitamin C is easily oxidized. Therefore, rapid cooking can reduce the effect of ascorbic acid oxidase. , alleviate oxidation reaction and protect vitamin C. Using airtight and light-shielding packaging and storing at low temperatures will also reduce the loss of vitamin C. Adding a certain amount of sulfite during canning also has a protective effect on vitamin C. 2.

Design of aseptic packaging container for juice Juice foods are instantaneously sterilized at high temperatures, and then the temperature is lowered to 20~30°C to meet the sterility requirements. Aseptic packaging of fruit juice food is a packaging system that places sterile juice, packaging containers and packaging auxiliary materials in a sterile environment, and uses an aseptic filling machine to fill and seal.

The packaging containers used in aseptic packaging include cups, boxes, bags, barrels, etc., and the packaging materials are mostly composite films. The quality of uk cigarette packaging cartons made of composite films is only 8% of that of glass bottles of the same volume. It not only has a lower cost, but also produces less waste, which is conducive to environmental protection.

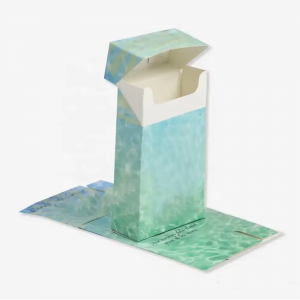

The structure and unfolding design of the aseptic packaging carton are shown in Figure 8-4. The material of the carton is composite film, which is composed of six layers of materials, namely polyethylene/paper/polyethylene/aluminum foil/polyethylene/polyethylene composite Material, of which 75% is paper, 20% is polyethylene, and the remaining 5% is aluminum foil.

The graphic printing, material compounding, cutting and creasing of the outer paper of the packaging carton are all completed by professional manufacturers and delivered to the packaging factory in roll form. The common brick-shaped sterile UK cigarette packaging carton on the market has a capacity of 250mL, and its dimensions are shown in Figure 8-4(b). The solid line in the figure represents the contour cutting line, the dotted line represents the indentation line of the inner fold, and the dotted line represents the indentation line of the outer fold. The packaging material roll transported to the packaging factory has a diameter of about 800mm and a length of about 800m. About 5,000 brick-shaped aseptic packaging cartons of 250m can be produced.

Drugs are a special commodity that affects human life and safety, so they must be produced at high quality to ensure their effectiveness. Security is qualitative. The Good Manufacturing Practice (GMP) for pharmaceuticals formulated by the World Health Organization (W0) is to implement comprehensive quality management in the pharmaceutical manufacturing process, such as the control of raw materials, quantity and final delivery, including the packaging operating procedures of pharmaceutical factories. There are clear regulations on the place, personnel engaged in packaging and the uk cigarette packaging containers, packaging materials, packaging equipment, packaging signs, etc. Strict requirements were put forward. In short, pharmaceutical packaging must be safe and reliable. Good protection. Easy to process. Promote sales, be economical, easy to use, transmit information and other functions

1. Uk cigarette packaging requirements for various medicines.

There are many types of medicines, and the technical requirements for packaging include 1) The impact of external factors on the shape of medicine bottles. Medicines are extremely susceptible to the influence of physical, chemical, microbial and climatic conditions. For example, in the air and dependence noodle. It is easy to oxidize and cause infection, is easy to decompose and change color when exposed to light, decomposes and deteriorates when exposed to moisture, and is easy to volatilize and soften when exposed to heat, thus causing the medicine to lose its efficacy. Sometimes, instead of curing the disease, it can cause illness and endanger life safety. so. Regardless of the shape, structure, decoration design and selection of packaging materials for pharmaceutical packaging, the first thing to consider is its protective performance, that is, maintaining the efficacy of the medicine. The average validity period of medicines is 2 years, and some can reach more than 3 years. Therefore, packaging should also ensure that the ingredients of the medicines are stable during the validity period and will not deteriorate. Different dosage forms of medicines deteriorate in different ways. Solid medicines such as tablets and powders are susceptible to moisture. When the temperature and humidity change, their shape and quality will gradually change. For example, after sugar-coated tablets become damp, the surface will deliquesce and will appear over time. Cracks will reduce the content of the main ingredients of the drug and reduce its efficacy. Another example is the sticking phenomenon of powders and granules after getting damp, which also reduces the efficacy and quality of medicines. Liquids or injections and other medicines are not susceptible to moisture, but they are prone to oxidation when in contact with the air, which will also change the main components of the medicine and cause discoloration. Or precipitation: Some medicines are easily contaminated by bacteria, mold, and fungi and deteriorate, completely losing their efficacy and becoming inferior products.

Viscous drugs such as softening agents will soften, or undergo oxidation and color changes under temperature changes and light exposure. 2 Drug packaging requirements. First of all, the patient’s psychological state and requirements must be taken into consideration, and sufficient information should be included to enable buyers to understand the ingredients and manufacturing background of the drug, its exact efficacy on the disease, and how to take it. The design should reflect a sense of security and trust and should be easy to use, carry and store. It should also be considered to be conducive to packaging automation to improve productivity. Table 8-6 shows the classification of pharmaceutical dosage forms and the packaging forms used for reference.

2. Design of pharmaceutical UK cigarette packaging protective functions.

Based on the pharmaceutical circulation environment, such as temperature, humidity, oxygen, light, etc., as well as the characteristics of pharmaceutical dosage forms, appropriate packaging processes and materials should be selected for protective packaging design. For medicines that are easily affected by moisture, moisture-proof packaging materials must be used.

The distribution of relative humidity on the earth changes with latitude. From the equator to near mid-latitudes (about 35°), the relative humidity decreases with increasing latitude. When changing from mid-latitude to high latitude, as the temperature gradually decreases, the relative humidity increases with increasing latitude.

The area south of the Yangtze River in my country is relatively humid, with an annual average relative humidity of 70% to 80% and an absolute humidity of 1.6 to 2.4kPa; the cumulative number of annual relative humidity times above 80% accounts for 50% of the total annual hours. The hours with 90% humidity account for more than 25% of the year. The annual average relative humidity in the Yellow River Basin is 70%, and the absolute humidity is 1.2kPa; Northeast China

The annual average relative humidity in the area is 70%, and the absolute humidity is only 0.8kPa.

Post time: Jun-05-2024