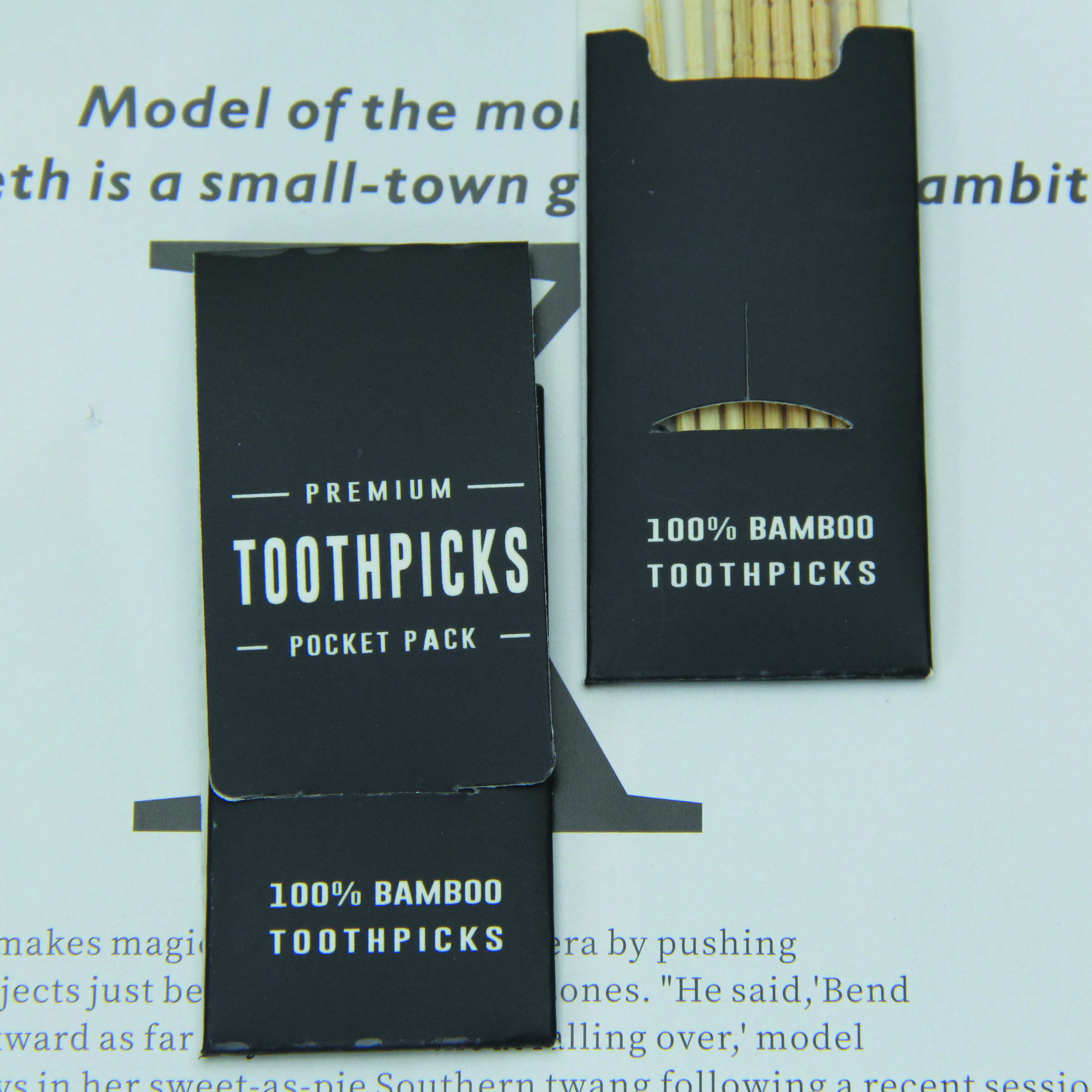

cutom antique box for toothpick boxes

cutom antique box for toothpick boxes

Since the beginning of the 21st century, our country has strongly proposed the development of science and technology, which has made many traditional hand-made products into digital, intelligent and mechanized manufacturing, which is environmentally friendly and renewable. This greatly improves production efficiency and saves time and cost. The same is true for the production and production of toothpick boxes, so the process in the production process of the packaging box:

1. First of all, the paper needs to be cut into the face paper of production specifications.

2. Put the facial paper on the intelligent printing equipment to print the facial paper.

3. Making a knife mold for beer, beer is an important part of the production process. In this link, the knife and die must be aligned, and the inaccuracy of the knife and die will seriously affect the finished product made of the entire packaging box.

4. For the over-glue of the facial paper, this process is to protect the facial paper from grinding and so on when the packaging box is produced.

5. Put the tissue card under the manipulator, and carry out a series of processes such as pasting the box, so that the semi-finished product packaging box comes out.

6. The assembly line transports the conventionally pasted box to the position of the automatic forming machine, and manually puts the pasted box on the forming mold, starts the machine, and the forming machine sequentially leads to the long side, folds into the long side, presses the short side of the blister pack, and presses the short side. Bubble, the machine will bounce the boxes onto the assembly line.

7. Finally, put the packaged box on the right through QC, fold it with cardboard, clean the glue, and detect defective products.

We need to pay attention to some details in the process of making the packaging box. Common problems need our attention: 1. Pay attention to the front and back of the facial paper during the beer process to prevent the facial paper from passing through the glue, resulting in the glue opening on the edge of the box. 2. Pay attention to the high and low angles when packing the box card, otherwise the box will be crushed on the molding machine. 3. When using the molding machine, pay attention to the fact that there is no glue on the brush, stick, and blade, which will also cause the glue to open on the edge of the box. 4. The thickness of the glue should be adjusted according to the different paper. It is not allowed to drip glue on the teeth or use water-based environmentally friendly white glue. 5. It should also be noted that the packaging box cannot have empty edges, glue opening, glue marks, wrinkled ears, burst angles, and large positioning skew (the machine positioning is set at about plus or minus 0.1MM). In the whole production process, the box needs to be used with a die before production.

Try out a sample, and then proceed to mass production after confirming that there is no problem, so as to prevent the possibility of modification if there is a problem with the die, and finally confirm that there is no problem before mass production. The box is well made.

Fuliter can make your products Better !

HOT-SALE PRODUCT

Quality First, Safety Guaranteed