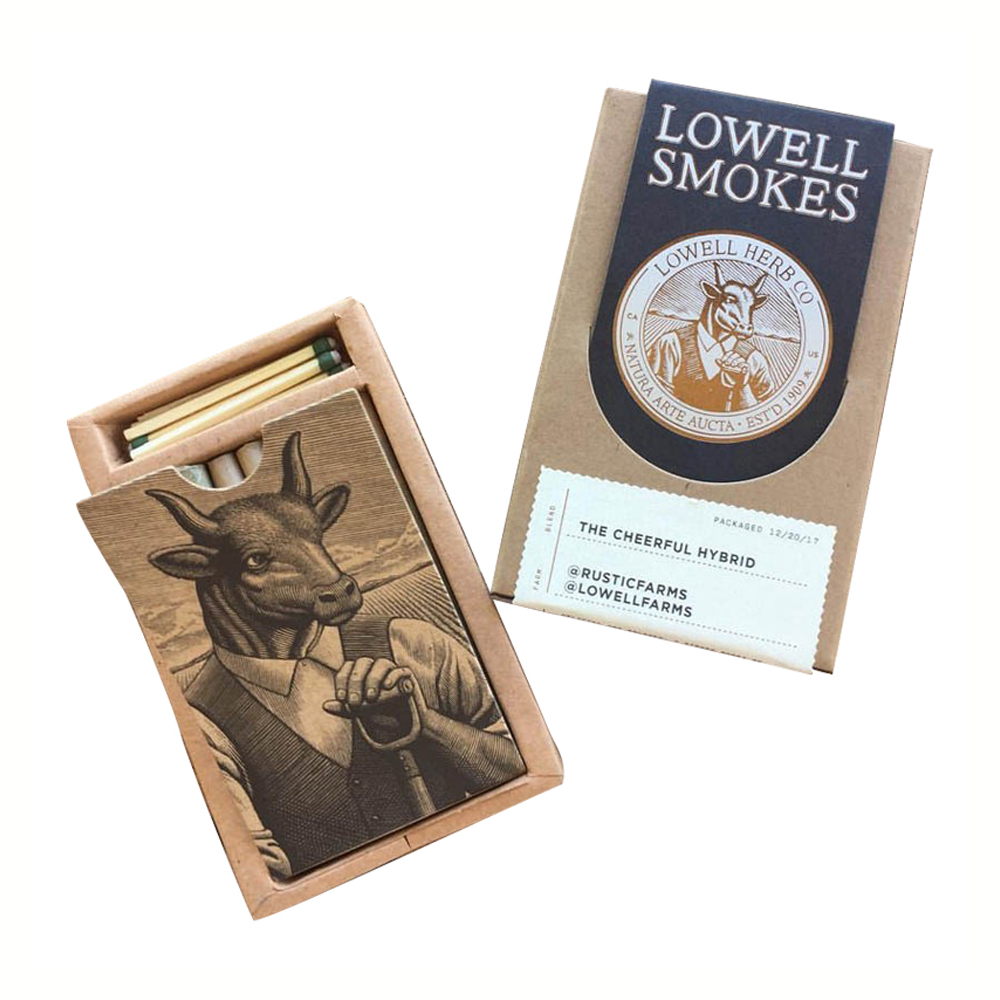

Costimized Empty Pre-Rolled Paper Box Packaging

Costimized Empty Pre-Rolled Paper Box Packaging

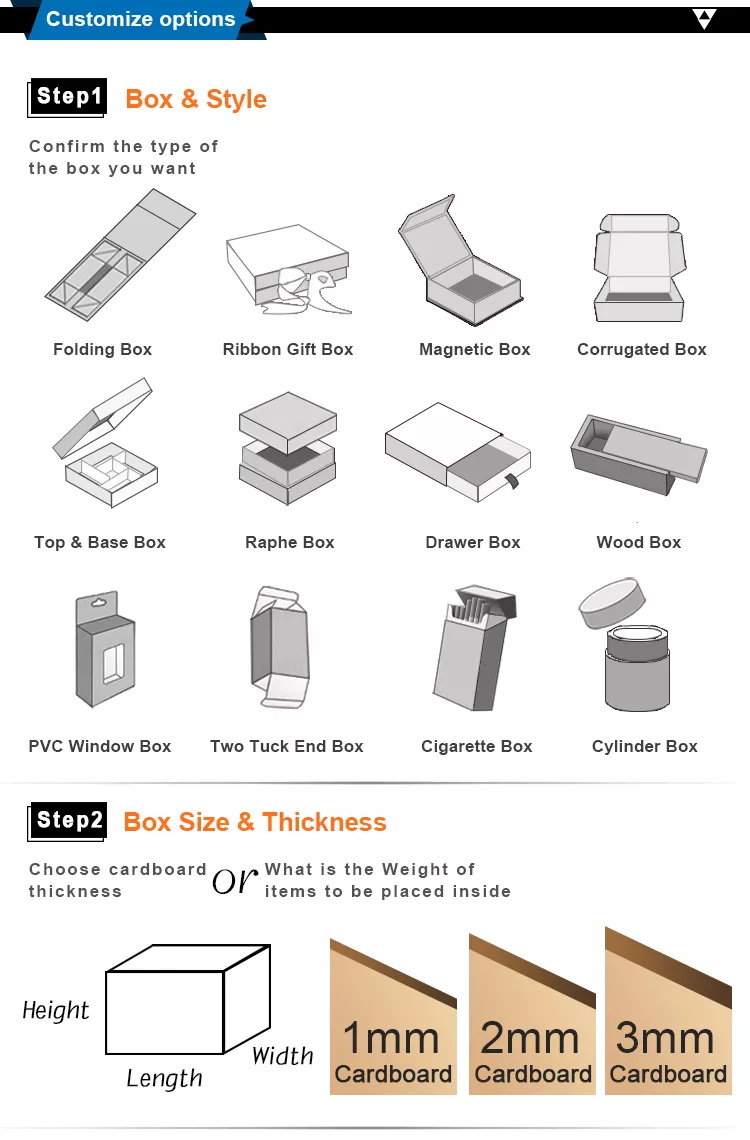

Specification

|

Dimensions |

All Custom Sizes & Shapes |

|

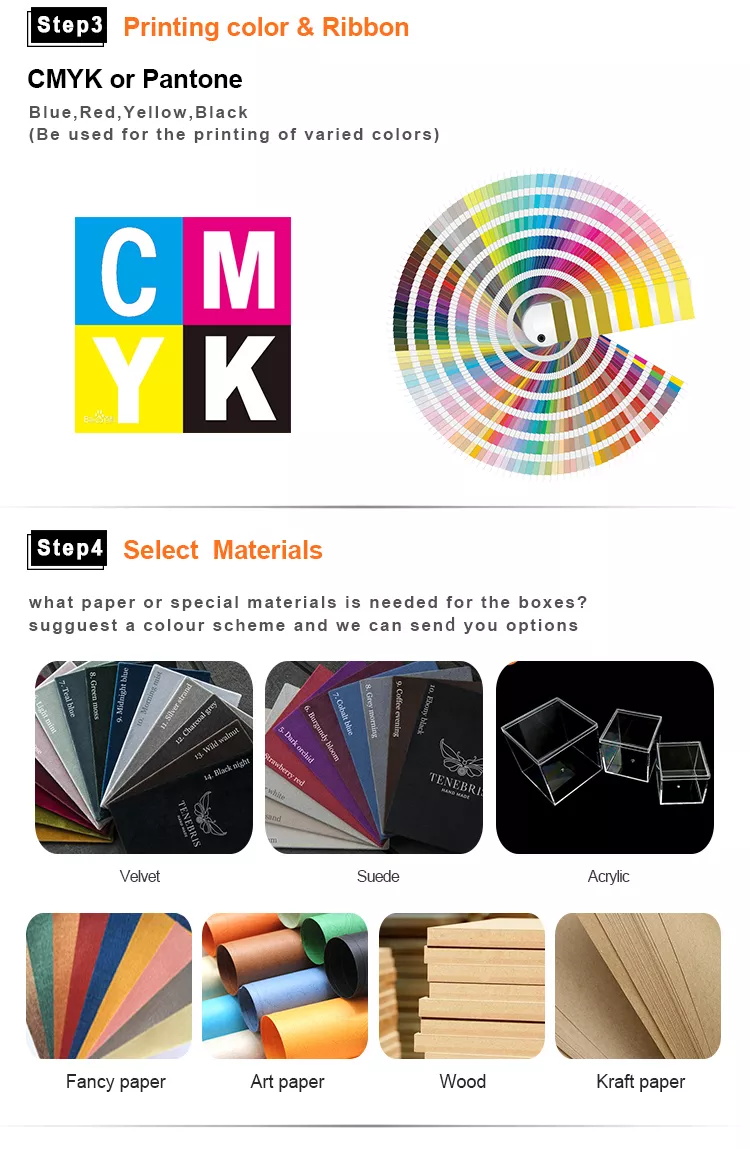

Printing |

CMYK, PMS, No Printing |

|

Paper Stock |

Coated Paper |

|

Quantities |

1000 - 500,000 |

|

Coating |

Gloss, Matte, Spot UV,gold foil |

|

Default Process |

Die Cutting, Gluing, Scoring, Perforation |

|

Options |

Custom Window Cut Out, Gold/Silver Foiling, Embossing, Raised Ink, PVC Sheet. |

|

Proof |

Flat View, 3D Mock-up, Physical Sampling (On request) |

|

Turn Around Time |

7-10 Business Days , Rush |

How do you design a cigar box?

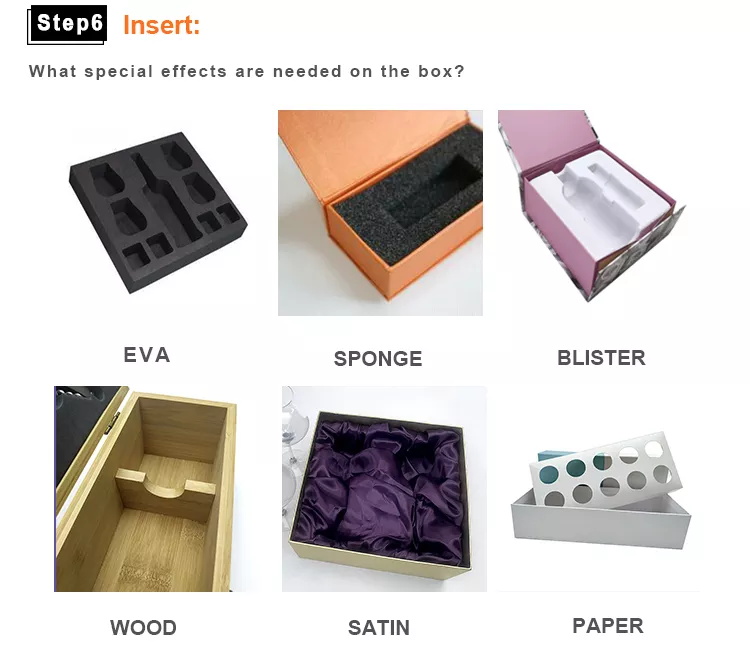

1. Interior decoration design: Consider adding appropriate internal stuffing inside the box to ensure the stability and protection of the cigar, and increase the texture and luxury of the box.pre roll packaging cigarette box tin

2. Pay attention to details: pay attention to the details of the packaging box, such as magnetic buckle, delicate process, exquisite hot stamping, etc., to improve the overall quality.pre roll packaging book style box

3. Product information and warning label: The packaging box should contain product information, such as cigar production location, model and storage conditions. In addition, appropriate warning labels are added according to legal and regulatory requirements.preroll cigarette boxes

4. Sustainability considerations: In order to comply with the concept of environmental protection, recyclable or reusable materials can be selected, and the packaging pattern is designed to make it easy to decompose and dispose of.Tobacco Box

How are cigarettes made?

Cigarettes have long been a subject of controversy and health concerns due to their harmful effects on human health. As the demand for cigarettes continues to rise, it becomes essential to understand the process behind their manufacturing. This article aims to shed light on how cigarettes are made and the various elements involved in their production.cigarette tin box suppliers

The first step in cigarette production is the cultivation of tobacco plants. Tobacco is mainly grown in countries with favorable climates such as Brazil, China, India, and the United States. These plants are carefully nurtured under controlled conditions to ensure optimal growth.cigarettes boxes and ceiling

After cultivation, the tobacco leaves are harvested and undergo a series of treatments to prepare them for manufacturing.cigarette box metal suppliers.First, the leaves are cured, which involves air-drying, flue-curing, or sun-drying to remove moisture. This process helps to improve the tobacco's flavor and aroma.eletric cigarettes.box

Once the leaves are cured, they are sorted and graded according to their quality. This step ensures that only the best leaves are used in the production of cigarettes. Leaves that are deemed to be of inferior quality are used for other tobacco products or discarded.blank cigarette boxes suppliers

After sorting and grading, the selected tobacco leaves go through a process called threshing.cigarette box new how.This involves separating the stems from the leaves. The stems, which contain little to no nicotine, are removed, leaving only the precious leaves behind.cigarette box airpod case

The next step is blending.cigarette packaging box metal.Different varieties of tobacco are combined to achieve the desired flavor and strength of the final product. This blending process requires expertise to create a consistent taste profile for the cigarettes.tube cigarette box case

Once the tobacco is blended, it goes through a process called stemming, which involves removing the central veins from the leaves. This is done to make the tobacco smoother and easier to roll into cigarettes.cigarette box plastic packaging

420 Lucky

Cartel Flowers

Coral Path

Guess Jeans

Homero Ortega

J.P.Morgan

J’Adore Fleures

Maison Motel

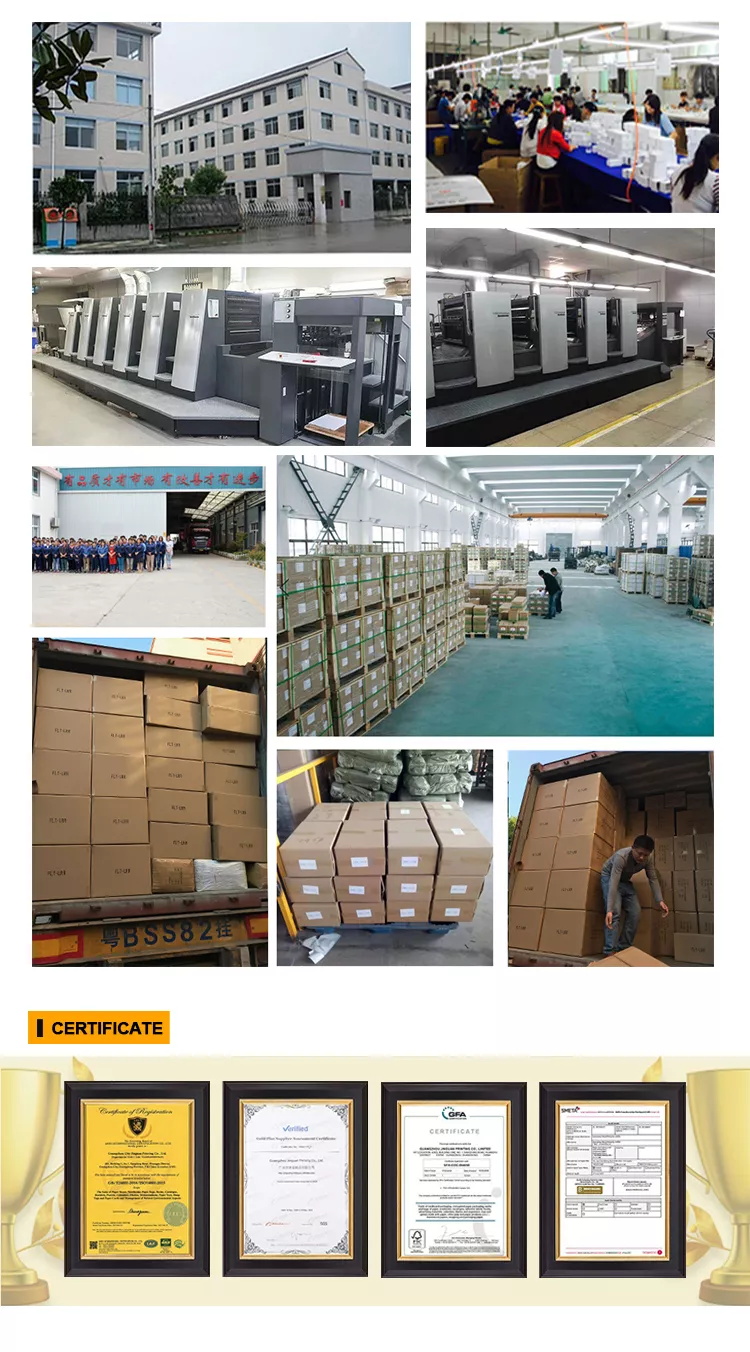

About us

Dongguan Fuliter Paper Products Limited was established in 1999,with more than 300 employees,

20 designers.focusing & specializing in wide range of stationery & printing products such as packing box、gift box、cigarette box 、acrylic candy box 、flower box、 eyelash eyeshadow hair box 、wine box 、 match box 、toothpick、hat box etc.

we can afford high quality and efficient productions. We have a lot of advanced equipment, such as Heidelberg two, four-color machines, UV printing machines, automatic die-cutting machines, omnipotence folding paper machines and automatic glue-binding machines.

Our company has integrity and quality management system, environmental system.

Looking ahead,we firmly believed in our policy of Keep doing better,make the customer happy. We will do our utmost to make you feel like this is your home away from home.

HOT-SALE PRODUCT

Quality First, Safety Guaranteed