Custom Size Candy Box Acrylic Cube Storage Container Box

Custom Size Candy Box Acrylic Cube Storage Container Box

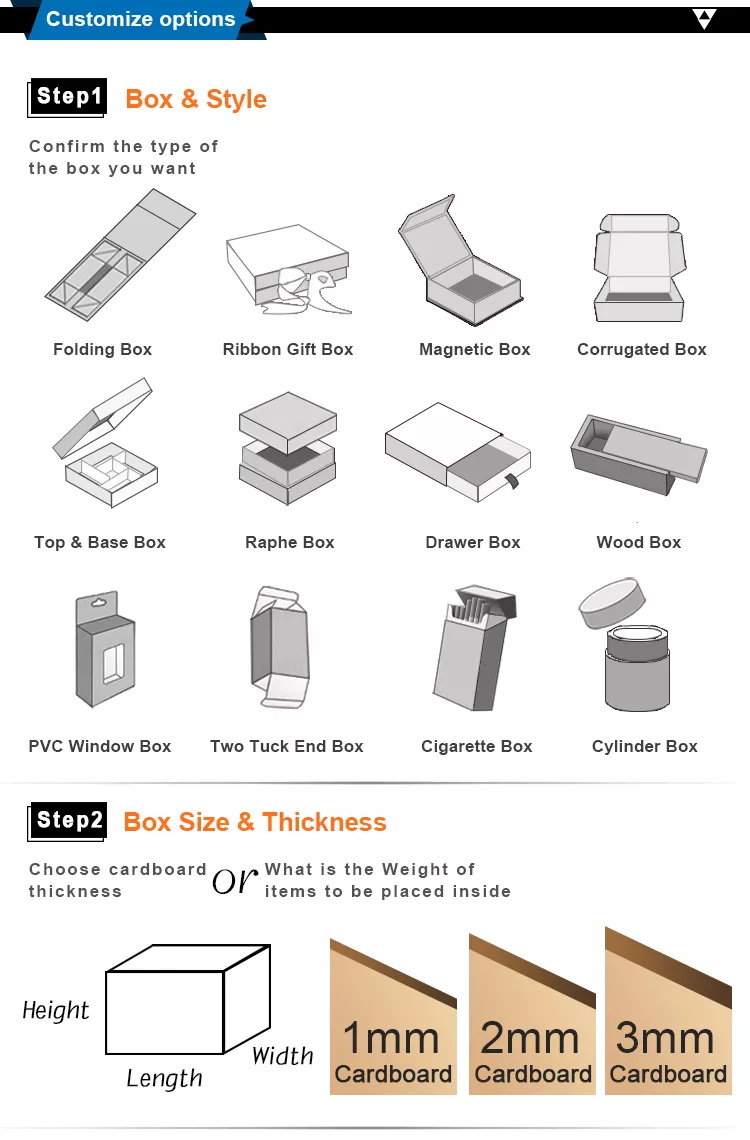

Specification

|

Dimensions |

All Custom Sizes & Shapes |

|

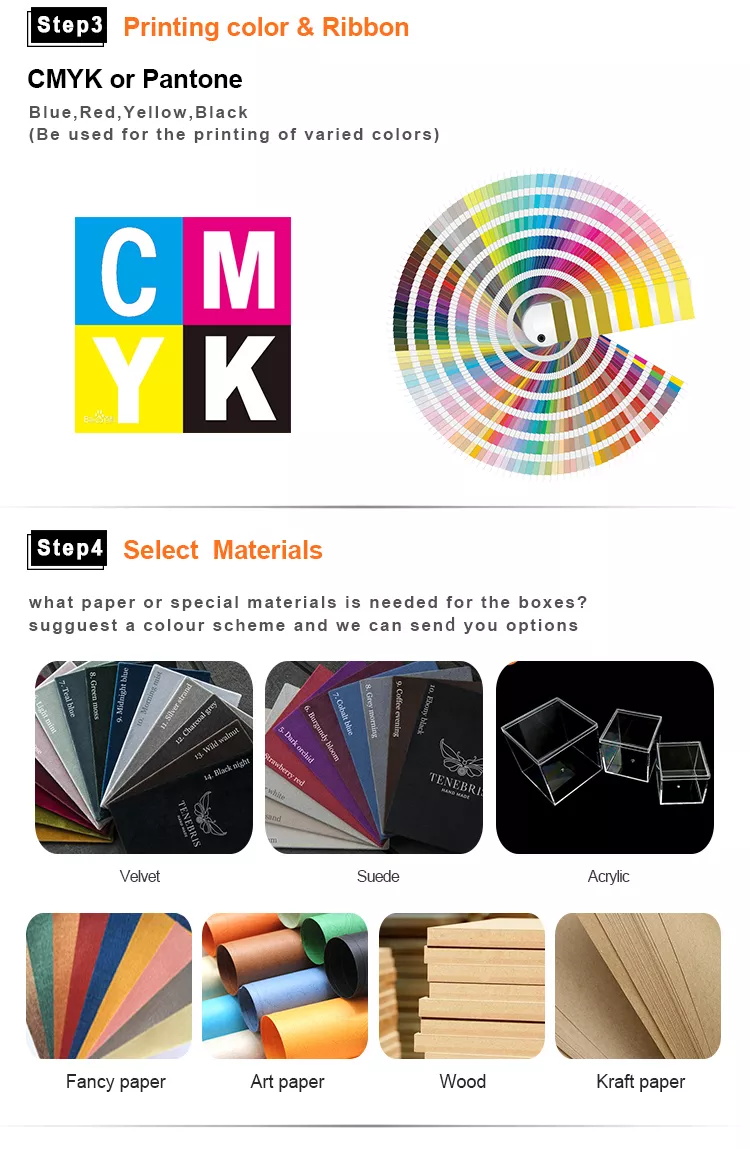

Printing |

CMYK, PMS, No Printing |

|

Paper Stock |

Acrylic |

|

Quantities |

1000 - 500,000 |

|

Coating |

Gloss, Matte, Spot UV,gold foil |

|

Default Process |

Die Cutting, Gluing, Scoring, Perforation |

|

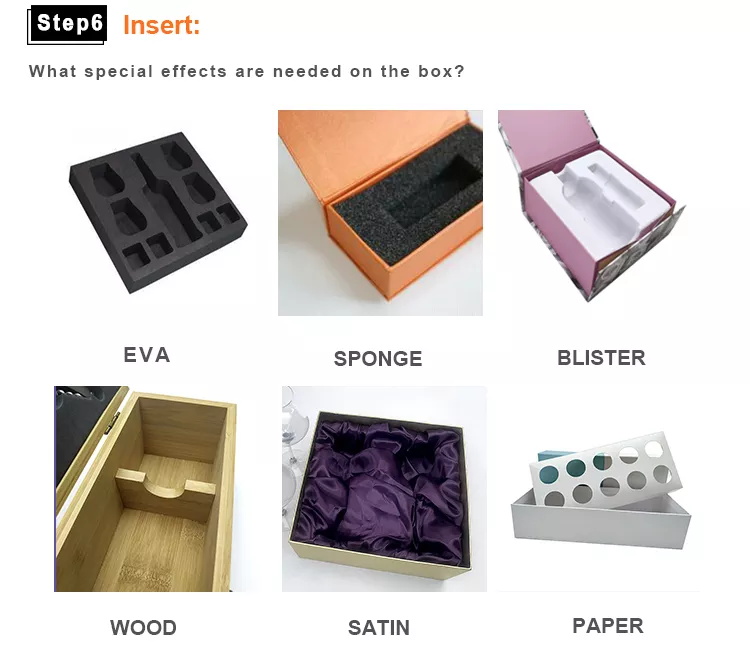

Options |

Custom Window Cut Out, Gold/Silver Foiling, Embossing, Raised Ink, PVC Sheet. |

|

Proof |

Flat View, 3D Mock-up, Physical Sampling (On request) |

|

Turn Around Time |

7-10 Business Days , Rush |

What is the attraction of transparent acrylic box packaging?

1. Beautiful appearance: Transparent acrylic box packaging has a clear and transparent appearance, which can show the appearance of the product and set off its beauty, so that consumers have a higher degree of affection for the product. candy box.2. Strong and durable: acrylic material has high strength and durability, which can effectively protect the product from damage or collision, and provide better protection during transportation and storage. wedding candy gift box for guest.3. Safe and reliable: Transparent acrylic box packaging materials are non-toxic and harmless, in line with health standards and environmental requirements, safe and reliable. wedding candy box.4. Multi-functional: Transparent acrylic box packaging can not only be used for packaging goods, but also can be used as a display and display box, suitable for various products and scenes.boxs candy

How is corrugated paper made?

Corrugated paper is made from pulp through a series of processing processes. The following is the production process of corrugated paper: 1. Pulp preparation: First, waste paper or wood is soaked, broken and bleached to make pulp. The quality and composition of pulp have a direct impact on the quality of corrugated paper. mini candy gift box.2. Press: the pulp is evenly distributed on the leakage board, and then through extrusion and pressing operation, the excess water is extruded to form a certain water content of the cardboard. candy packaging tin box cookies candy tin box.3. Corrugated paper core production: Roll up a layer of pressed cardboard through the reel machine to form a paper core. The shape of this layer of cardboard core determines the wave shape of the corrugated board. acrylic small candy box.4. Bonding: Cover a layer of front cardboard called face paper on the paper core, and then cover another layer of cardboard called bottom paper. The face paper, core paper and base paper are bonded together by hot pressing or spraying water. candy packaging boxes.5. Drying and cutting: The bonded cardboard enters the drying line and is dried in a high temperature and low humidity environment. The cardboard is then cut to the appropriate size and shape.acrylic shadow box. 6. Packaging and transportation: Finally, the corrugated paper is packaged according to demand to ensure that it can remain intact and non-destructive during transportation. This is the basic process of making corrugated paper.acrylic ring box. According to needs, process steps such as adding special treatment and coating can be carried out to enhance the water resistance, pressure resistance, moisture resistance and other properties of corrugated paper.booster box acrylic case

420 Lucky

Cartel Flowers

Coral Path

Guess Jeans

Homero Ortega

J.P.Morgan

J’Adore Fleures

Maison Motel

About us

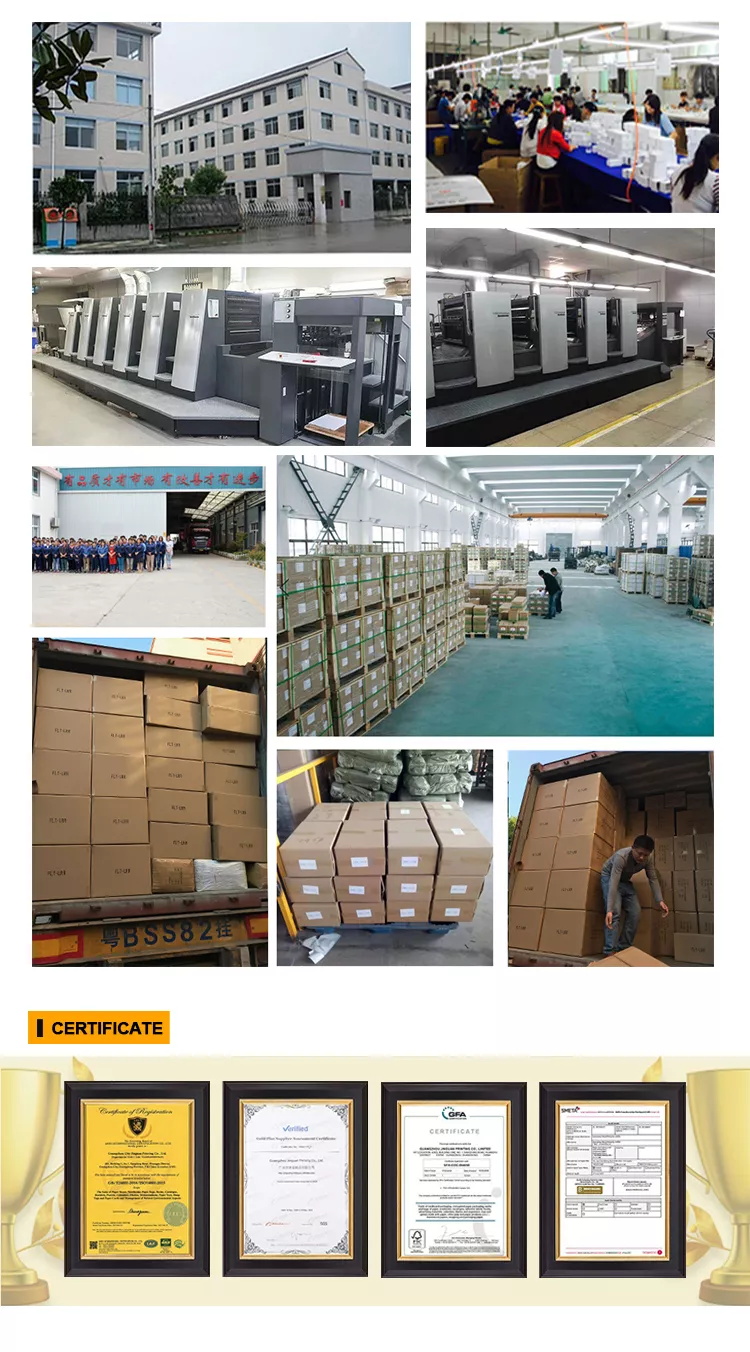

Dongguan Fuliter Paper Products Limited was established in 1999,with more than 300 employees,

20 designers.focusing & specializing in wide range of stationery & printing products such as packing box、gift box、cigarette box 、acrylic candy box 、flower box、 eyelash eyeshadow hair box 、wine box 、 match box 、toothpick、hat box etc.

we can afford high quality and efficient productions. We have a lot of advanced equipment, such as Heidelberg two, four-color machines, UV printing machines, automatic die-cutting machines, omnipotence folding paper machines and automatic glue-binding machines.

Our company has integrity and quality management system, environmental system.

Looking ahead,we firmly believed in our policy of Keep doing better,make the customer happy. We will do our utmost to make you feel like this is your home away from home.

HOT-SALE PRODUCT

Quality First, Safety Guaranteed